Healthmark Industries is proud to present the “Quick Comply” starter kit for your Endoscopy / GI departments.

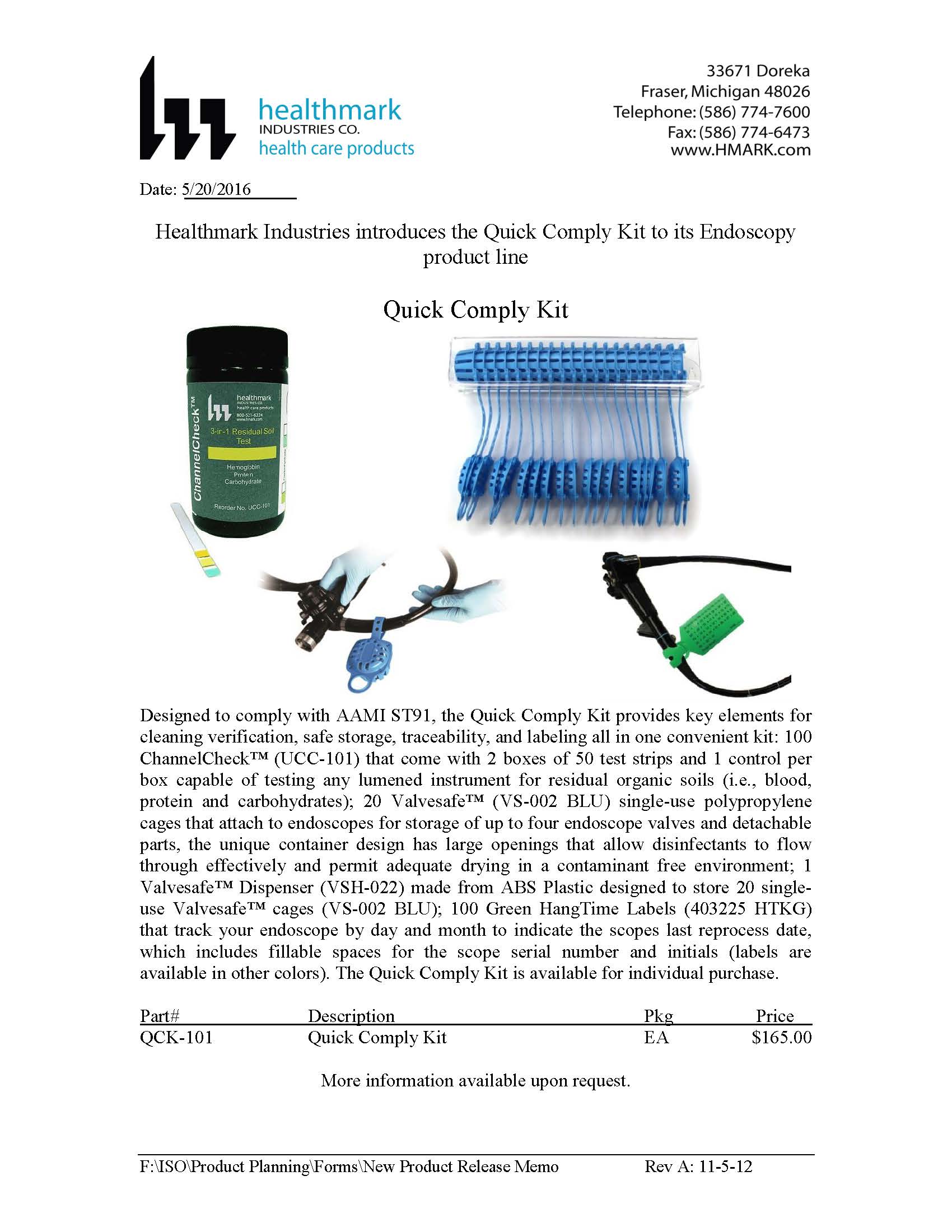

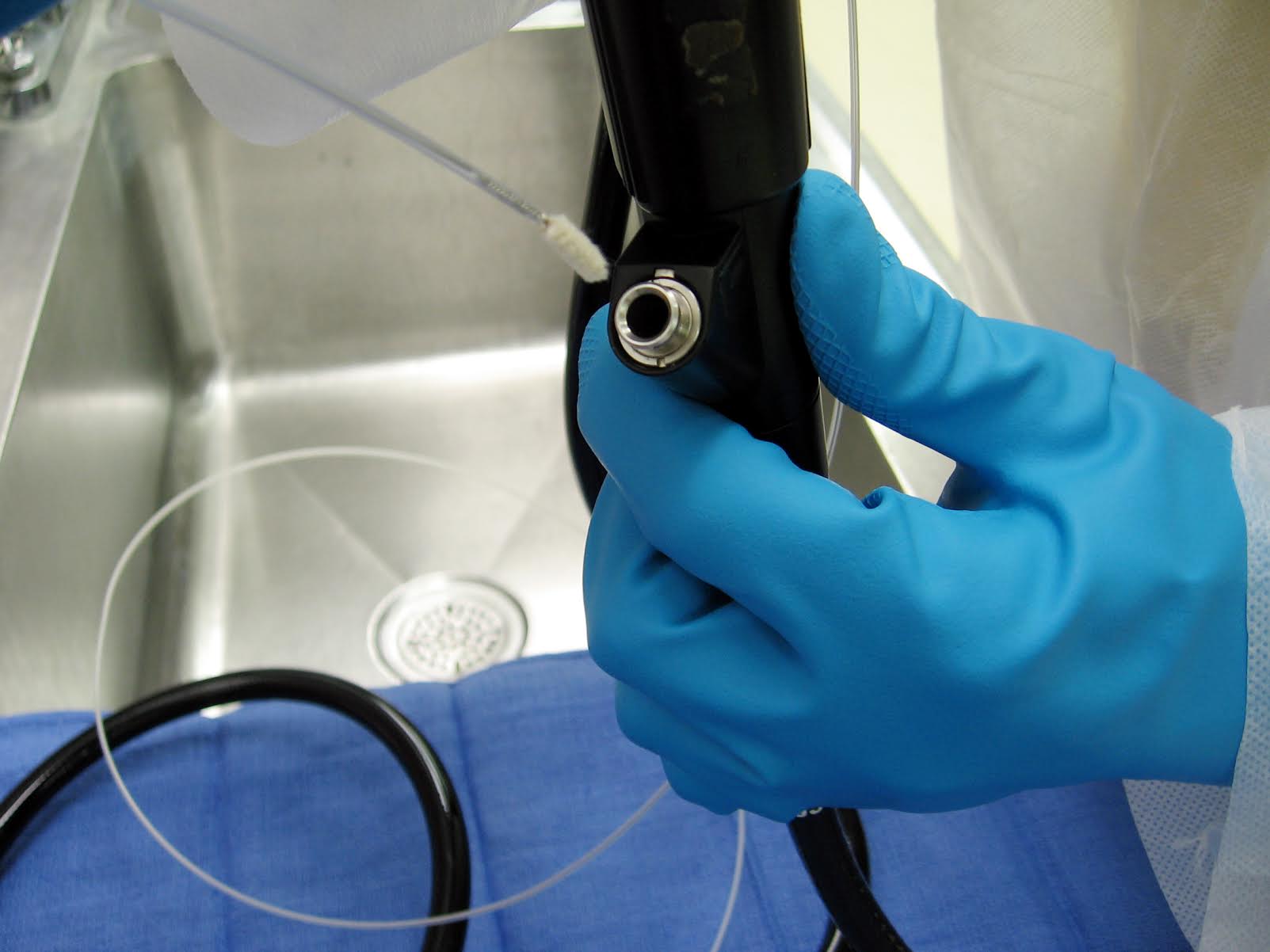

Designed to comply with AAMI ST91, the Quick Comply Kit provides key elements for cleaning verification, safe storage, traceability, and labeling all in one convenient kit: 100 ChannelCheck™ (UCC-101) that come with 2 boxes of 50 test strips and 1 control per box capable of testing any lumened instrument for residual organic soils (i.e., blood, protein and carbohydrates); 20 Valvesafe™ (VS-002 BLU) single-use polypropylene cages that attach to endoscopes for storage of up to four endoscope valves and detachable parts, the unique container design has large openings that allow disinfectants to flow through effectively and permit adequate drying in a contaminant free environment; 1 Valvesafe™ Dispenser (VSH-022) made from ABS Plastic designed to store 20 single-use Valvesafe™ cages (VS-002 BLU); 100 Green HangTime Labels (403225 HTKG) that track your endoscope by day and month to indicate the scopes last reprocess date, which includes fillable spaces for the scope serial number and initials (labels are available in other colors). The Quick Comply Kit is available for individual purchase.

Part# Description Pkg Price

QCK-101 Quick Comply Kit EA $165.00

More information available upon request. Email US or Call: 713-640-5393